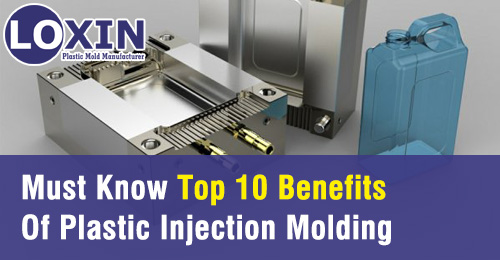

Must Know Top 10 Benefits Of Plastic Injection Molding

Plastic injection molding technology has been widely used. You can find this technology in your toddler’s toy and even in race cars. Manufacturers prefer injection molding technology due to its number of benefits. This is used to create different plastic parts and designs. In the current condition, it is one of the most popular manufacturing processes used in the plastic parts mass production.

You might be thinking about what makes it different from the traditional molding techniques. The key benefit of this advanced technology is that it can be used to create different shapes, sizes, designs, finishes, and intricacy. You cannot expect all these from your conventional molding techniques. Here are 10 other benefits that you can expect from the plastic injection molding.

1. Flexibility

Flexibility is one of the key benefits of plastic injection molding. Manufacturers use this technology to get any shape and size. They can create precise designs. Also, it is flexible in terms of color choice. In addition to flexibility, you can expect better accuracy than the conventional option.

2. Accuracy

Plastic injection molding is a unique method that can fabricate almost all types of plastic parts. There will be certain design restrictions. However, the molds make the final and finished product very precise. The accuracy will be within 0,005 inches.

3. Faster Result

Plastic injection molding is considered best since it is popular for offering faster results. The speed will depend on the complexity of the mold. It generally takes fifteen to thirty seconds between cycle times. The faster result offers more effective solutions to the manufacturers.

4. Low Labor Cost

Another benefit is the low labor cost. Once you use this technology, you will not have to spend much on labor. Plastic injection molding equipment will run with an automatic and self-gating tool. The automatic tool will keep the production ongoing and the operation streamlined with minimal human intervention. As a result, you will not have to hire more manpower for production.

5. High Strength

In plastic injection molding, fillers can be added inside the injection molds. The fillers can use different strengths such as mica, carbonate, silica, calcium, clay, glass, and a few others. These fillers will add strength to the end product. Also, fillers will reduce the density of the plastic.

6. Smooth Finishing

Plastic injection molding offers a smooth finished appearance. The surface finish will be excellent and all the parts that will come from the mold will look impressive with the finished appearance. You cannot expect such an outcome from the conventional technique.

7. Cheaper in the Long Run

Initially, plastic injection molding might be expensive. You will have to spend a little more upfront. But once you have the mold, you can produce a large volume of the plastic without costing much. Plastic machining can cost you twenty-five times more than injection molding.

8. Waste Reduction

Plastic injection molding will produce less waste compared to conventional techniques. It will serve the environment and will help us to move towards a greener world. Also, the generated plastic can be recycled by using the art machinery.

9. Co-injection Molding

The plastic injection molding can process two different materials in the same mold. Therefore, you can use it to get more strength.

10. Wide Acceptance

Plastic injection molding is very popular among manufacturers. They find it worth spending since this technology helps with precise designs, high durability, and enhanced strength. With traditional techniques, they will not get the same benefit. The process will be longer and the finishing will not be that smooth and accurate.

Plastic Injection molding is popular among manufacturers. If you are looking for the best China Mold Manufacturer, you can consider Loxin Plastic Mold Manufacturer. This Mould Design Company has more than one and a half decades of experience in this industry. With Loxin, you will find affordable and fast solutions.

In addition to affordability, the company is thoroughly experienced to take care of your specific needs. The products will be traded at the factory price. Also, these are quality made and will offer a durable result. The communication will be transparent. The company will discuss all your unique needs to create a suitable option for you. You can contact Loxin Plastic Mold Manufacturer to discuss your requirements. All you need to do is to fill the given form on their website. They will get back to you with a customized solution.

Your Best China Molding Factory For Injection Plastic Industry

Your Best China Molding Factory For Injection Plastic Industry

How Dose Plastic Injection Moulding Process steps from China

How Dose Plastic Injection Moulding Process steps from China

LOXIN Mold

LOXIN Mold

Leave a Reply

Want to join the discussion?Feel free to contribute!